Is That All You’ve Got?!

Is That All You’ve Got?!

As a network of supportive professionals – both new and seasoned – we Certified Ergonomic Assessment Specialists (CEAS) affiliated through The Back School Network (TBSN), are often called upon to solve common problems faced by one and all. That’s fair enough. We’re here to help one another learn and grow.

As attractive as it might sound, sometimes the problem we’re called on to solve doesn’t have one single ‘silver bullet’ answer. And sometimes, our client – who might themselves possess a high sophistication-level – expects a little more honest-to-goodness elbow grease on our part. They want to see us ‘work for it’.

As if that weren’t enough, our client often has very real budgetary constraints which can dictate what intervention we might suggest. We shouldn’t let this be discouraging. Quite often, it allows us to expand our scope and provide a series of solutions. On the bright side, this might better turn an otherwise ‘one-and-done’ client into a long-term, trusted professional relationship. Allow me to explain.

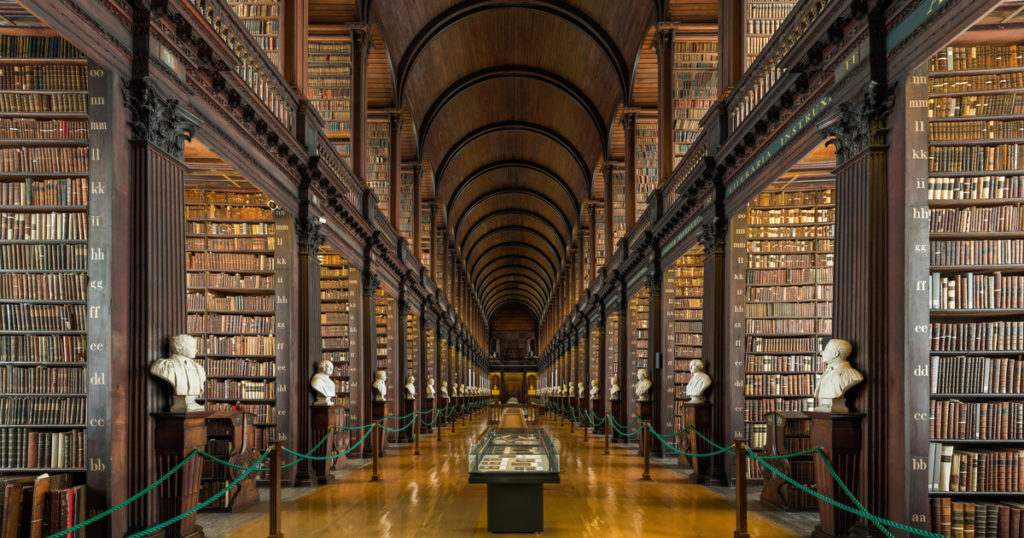

‘When Asked for a Book – Offer a Library’

As a valuable guide through this process of offering more than one answer to multi-causal ergonomic problems, we can confidently turn to the NIOSH Hierarchy of Controls (https://www.cdc.gov/niosh/topics/hierarchy/default.html ). This source provides both us and our clients a spectrum of interventions to solve their puzzle. It’s a two-dimensional approach that works both vertically (efficacy-based) and horizontally (chronologically-based). It usually looks something like this:

‘Nothing is Intolerable that is Necessary’ – Jeremy Taylor

Most times, the ‘Hard Controls’ such as Elimination (physically removing the ergonomic hazard) or Substitution (replacing the ergonomic hazard) are the two best options. Everything else seems like a band-aid in comparison. From our vertical, efficacy-based perspective, this may initially make the most sense. Once it’s done, its done. If Elimination or Substitution can’t be immediately implemented however, there ARE other Hard Control options.

Namely – Engineering (automating to remove people from the ergonomic hazard) or Segregation (physically isolating people from the ergonomic hazard). Like the two previously mentioned ‘Hard Controls’, these too can be both expensive and relatively difficult to implement in an already fully operational system. However, all is not lost.

This is where our chronological thinking kicks-in. While cost / difficulty doesn’t put these harder controls out of the running, it may just put them off on the calendar. In a future budget cycle, resources can be earmarked and allocated to make a full, ‘Hard Control’ investment. Knowing this means we can make ‘softer’ inroads in the interim to prepare our client’s workplace for these harder controls to follow. Here are some simple examples of ‘Hard Control’ suggestions:

| Ergonomic Exposure | ‘Hard Control’ Suggestion Samples |

| Applying Straps for a Hoist – Postural exposure includes working from the floor. The staff may work from a forward bent low back position repeatedly. | Purchase mechanization in the form or an electric lift truck or powered pallet jack would allow securing the load at a more ergonomically appropriate height. |

| Internal Grinding Task – Postural exposure includes forward bent low back positioning. Reaching distance beyond a base of support exposes low back & shoulders. | Purchase and installation of adjustable workstations with an angular or cambered approach for proper working height. An upright chest / head level eliminates exposure. |

| Parts Assembly on Table – Postural exposure due to angle of approach from only from one side. This causes uneven unilateral risk over the length of the task on a daily basis. | Purchase and installation of a Lazy Susan table to allow a rotating surface. This addition can adjust the working surface throughout the task performance. |

| Hoist Product from Pallet to Table – Postural and force exposures are due to pallet stacking from floor. Repeated low back exposure results from repeat forward bending. | Purchase and install overhead hoists, jib cranes, mechanized electric pallet jacks and / or lift trucks to be applied at multiple stations when moving product. |

| Workstation Layout – Postural exposure due to workstation controls and supply bins only on one side. Unilateral shoulder elevation and reach distance risk. | Purchase and distribute workstation bins, tools, controls etc. on both sides of work stations to encourage bilateral access and use. |

‘[Sometimes] What is Soft is Strong’ – Lao Tzu

‘Soft Controls’ like Administrative (changing policies on how people work with an ergonomic hazard) and Personal Protection (involving employee responsibility with an ergonomic hazard) are not nearly as effective as our ‘Hard Controls’. Yet, they can bridge the chronological gap between immediate, rapid response and future, lasting solutions. But be forewarned. They may seem at first inexpensive to establish but – over the long term – they can be very costly to sustain. It only takes one OSHA-Recordable, lost-time Worker’s Compensation claim to burn-through any initial savings. And the costs compound from there. Still, as temporary measures, they may suffice. Here are some of our ‘Soft Control’ examples:

| Ergonomic Exposure | ‘Soft Control’ Suggestion Samples |

| Angular pneumatic tool – Postural exposure due to tool primarily designed for working on vertical surfaces so wrist and forearms are neutral and elbows stay inward. | Write policies and train workforce in tool / target / task of appropriate work actions. Write an onboarding policy requiring new hire education on proper tool application. |

| Grinding and Buffing Parts – Loud noise from power tools and strong lighting required to detect imperfections exposes workers to extreme auditory and visual risk. | Write and enforce hearing protection and eye protection standards for all employees. Include training for both incumbent staff and new hires regarding these policies. |

| Angular Pistol Grip Grinding Tool – Postural exposure due to inappropriate use on horizontal surfaces will require wrist torsion, shoulder abduction and neck exposure. | Provide onboarding policies and training to new hires in appropriate tool, target and task. Pistol grip tools are best applied for work on vertical, upright surfaces. Enforce it. |

| External work with hand tools – Postural exposure due to preferred position of attack in task, causing repeat exposure of neck, shoulders, wrists and forearms. | Provide proper body mechanics policies and training of incumbent staff and new hires to aim at maintenance of optimal working posture during ANY task performance. |

| Parts transfer from table to dolly – Postural exposure due to the reach and lift outside the base of postural support due to the part’s distant and awkward position on table. | Implement two-man lift / lower policy and training on all parts over 20 lbs. Require staff to contact co-workers when lifting / lowering parts to lessen injury exposure. |

‘Perfect is the Enemy of Good.’ ― Voltaire

While this hierarchical approach is sometimes more time-consuming, it tends to alleviate the ‘silver bullet’ mindset syndrome. As ergonomic problems can many times be multifactorial and multi-causal, so too are often their solutions. This longer perspective, chronological and multiphasic understanding better helps us honor and apply our global perspective to ergonomic problem solving.

When we recognize the dynamic interplay and influences of the work, the workers and the workplace, we can see how the Hierarchy of Safety Controls better helps us see ‘the big picture’. By taking the broader view, we can then plan our interventional hierarchy over a progressive, evolving framework.

We avoid oversimplifying, as we avoid the trap of either / or thinking. And, we begin to see the spectra of influences and possibilities at play. This adds arrows to our problem-solving quiver as we approach our work from many sides with many options. Knowing this, we can be certain we offer our clients the best possible service. And the word spreads. This is how a lasting ergonomics and prevention practice is built. One satisfied client at a time. Brick by brick. Taking the long-view. In many cases, time is on our side.

A little about our author, Matt Jeffs DPT PSM CEAS –

Dr. Jeffs is a safety management advisor for national and international firms. He’s also a seasoned ergonomics educator here at The Back School. Years ago, he excelled as a big-wave surfer and an experienced ocean lifeguard with numerous rescues, prior to earning both his undergraduate and doctorate degrees in physical therapy.

He now serves as a Tai Chi Fitness Instructor in multiple settings – including the modern workplace. Through his unique approach to ‘Meta-Physical Therapy’, Mind-Body Awareness is taught, learned, and cultivated into safer, healthier and more productive work environments.

Dr. Jeffs applies his quirky and unconventional long-term perspective to many undeservedly contentious trends. He hopes offering insight on how to make them work – for the most people possible – is a goal worthy of us all.